Description

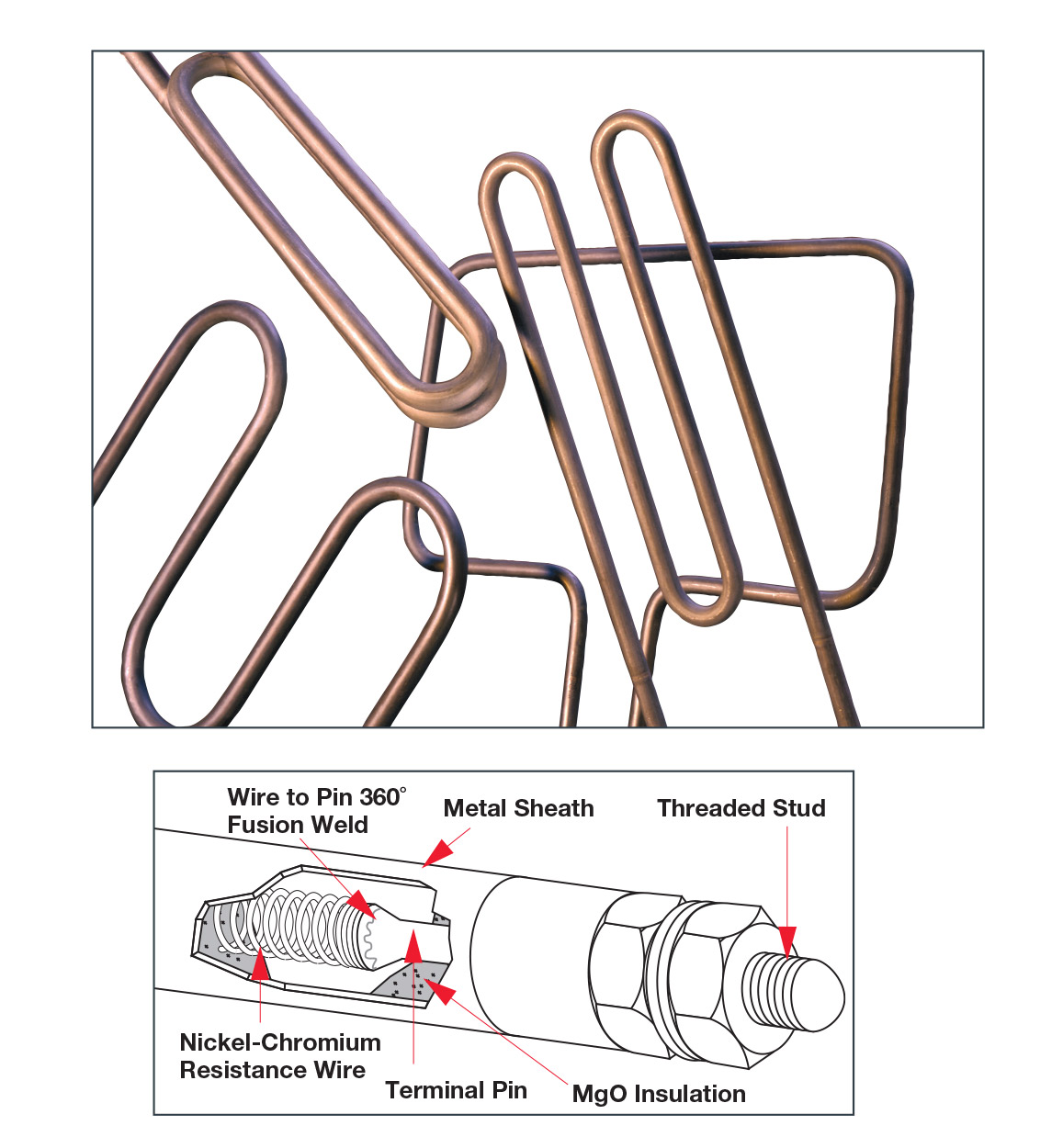

Watlow Watrod Tubular Heaters fit virtually entire range of immersion and air heating applications. Moreover, they are available in single or double-ended termination styles, versatile, and economical WATROD tubular heating elements.

Watlow WATROD Tubular Heater Types

The single-ended WATROD tubular heater design has both terminals at one end. The opposite end is sealed. Flexible lead wires are 12 inch (305 mm) crimp connected to the terminal pin and have silicone-impregnated fiberglass oversleeves.

The double-ended WATROD, with its round cross-sectional geometry, are highly adaptable for bending – especially when bending is performed in the field. Watlow’s double-ended MULTICOIL tubular elements offer various combinations of resistor coils and thermocouples inside one sheath. They have the ability to sense the heater’s internal temperature accurately every time or offer three-phase capability in one element.

In addition, both single and double-ended WATRODs share many construction features delivering long life. The resistance wire is centered in the heater sheath. They are electrically insulated with compacted, high-grade magnesium oxide for superior heating performance.

Moreover, the Watlow WATROD tubular heating elements have a variety of mounting and termination options making them highly popular among industrial customers. They vary in material, such as: Single-Ended and Double-Ended Alloy 800/840, Single-Ended and Double-Ended Stainless Steel, and Double-Ended Steel. In summary, operating temperatures and watt densities vary depending on product type and application.

WATROD Heater Performance Capabilities

Single-Ended Watlow WATROD Tubular Heaters

- Watt densities up to 45 W/in2 (6.9 W/cm2)

- UL® and CSA component recognition up to 240VAC

- Alloy 800/840 and stainless-steel sheath temperatures up to1200°F (650°C)

Double-Ended Watlow WATROD Tubular Heaters

- Watt densities up to 120 W/in2 (18.6 W/cm2)

- UL® and CSA component recognition up to 600VAC

- Alloy 800/840 sheath temperatures up to 1600°F (870°C)

- Stainless steel sheath temperatures up to 1200°F (650°C)

- Steel sheath temperatures up to 750°F (400°C)

- Alloy 800 sheath temperatures up to 1800°F (982°C)

Watlow Watrod Tubular Heater Features and Benefits

Precision wound nickel-chromium resistance wire

- Distributes heat evenly to the sheath for optimum heater performance

Silicone resin seals

- Protects against moisture contamination and is rated to221°F (105°)

MgO insulation filled sheath

- Maximizes dielectric strength, heat transfer and life

Standard sheath materials

- Steel, 304 and 316 stainless steel, alloy 800/840 and alloy 600

53 standard bend formations

- Allows forming the heating element to the application. Spirals, compound bends and multi-axis and multi-plane configurations available.

Stainless steel studs

- Fusion welded to terminal pins for mechanical strength

We provide engineering and product support for your application.