Description

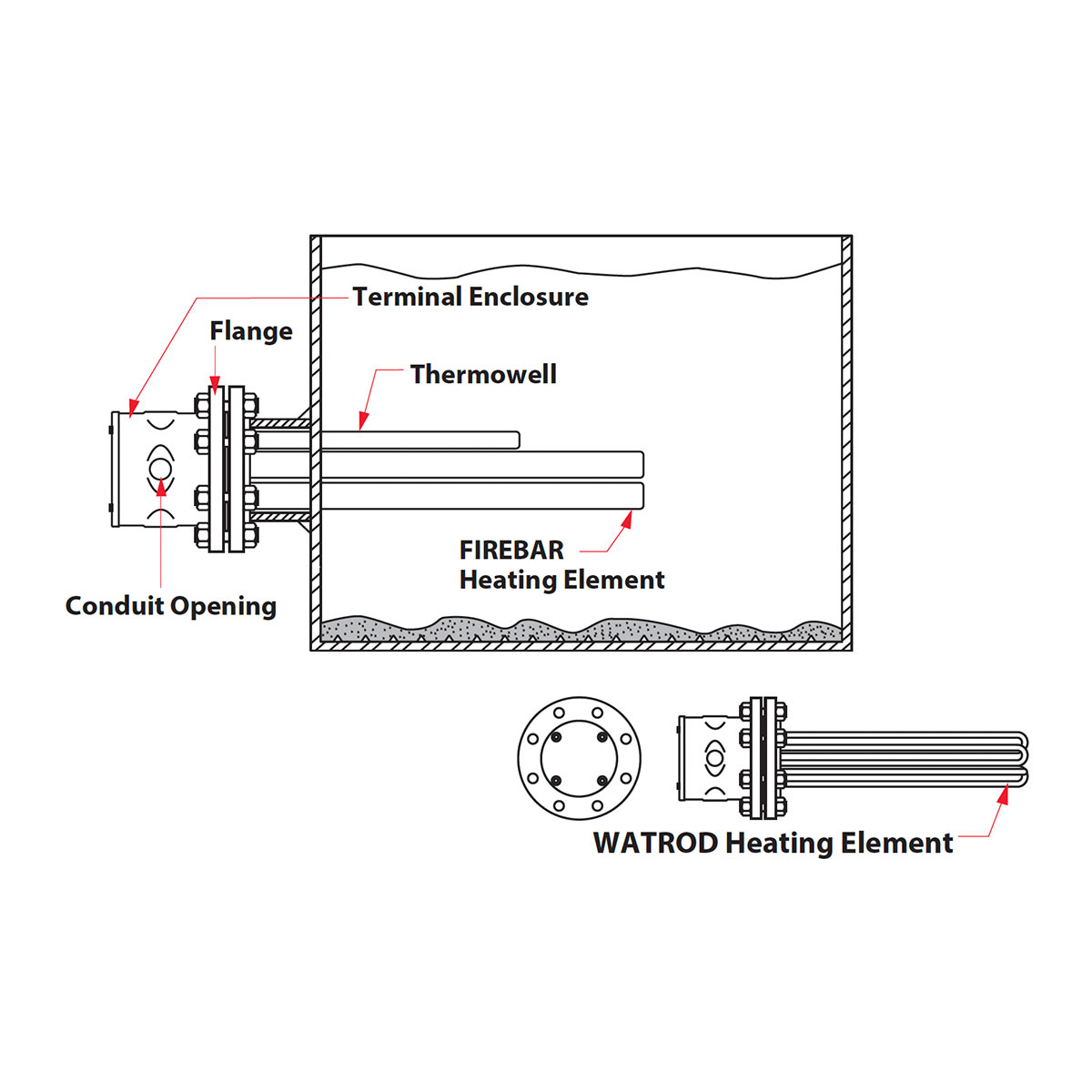

Watlow flange immersion heaters are easy to install and maintain. Design for heating liquids and gases in tanks and pressure vessels, ANSI flange immersion heaters are ideal for applications requiring higher kilowatts. The Watlow flange immersion heater is made with WATROD or FIREBAR tubular elements and use braze or welding to a flange. Stock flange heaters come equip with a general purpose terminal enclosure. Watlow flange immersion heaters, with FIREBAR elements, also answer the need for liquid immersion applications requiring high kilowatts in small tanks. The FIREBAR element’s unique flat surface geometry packs more power in a smaller bundle, with lower watt density, making it especially well-suited for petroleum-based liquid heating applications.

Watlow Flange Immersion Heater

Watlow flange heaters possess IECEx and ATEX Ex’d’ or Ex’e’ ratings certifying that the flange heater enclosure is flameproof. Every enclosure has pressure testing to ensure heaters are safe and reliable and meet rigorous standards for electrical safety.

Flange heaters, with FIREBAR elements, also answer the need for liquid immersion applications requiring high kilowatts in small tanks. The FIREBAR element’s unique flat surface geometry packs more power in a smaller bundle, with lower watt density, making it especially well-suited for petroleum-based liquid heating applications.

Performance Capabilities of Flange Immersion Heater

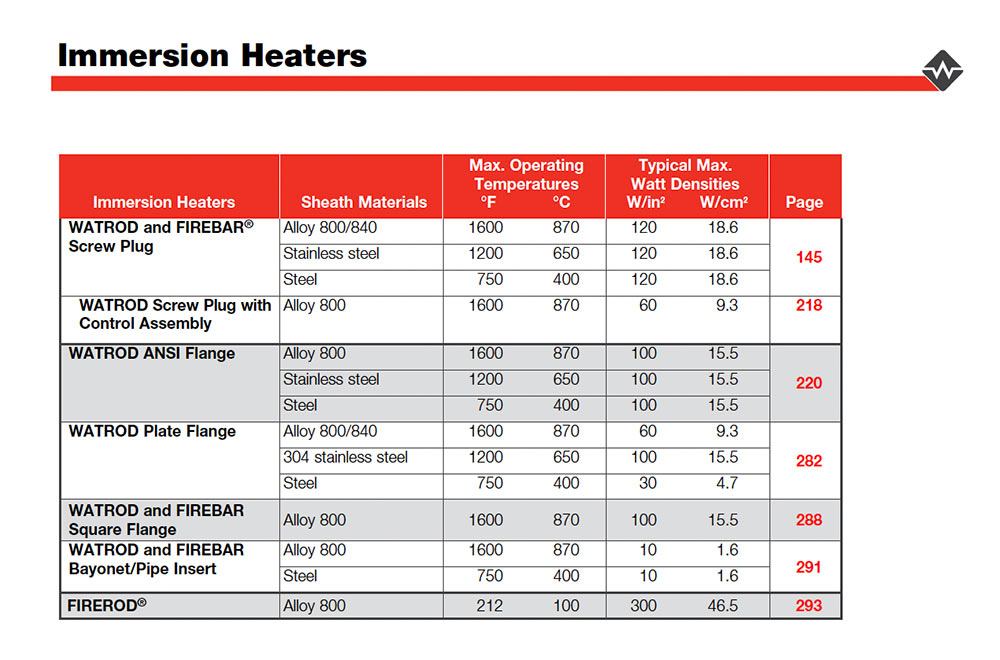

- Watt densities up to 100 W/in2 (15.5 W/cm2)

- Wattages up to three megawatts

- UL and CSA component recognition up to 600VAC

- Alloy 800/840 sheath temperatures up to 1600°F (870°C)

- Passivated 316 stainless steel sheath temperatures up to 1200°F (650°C)

- 304 stainless steel sheath temperatures up to 1200°F (650°C)

- Steel sheath temperatures up to 750°F (400°C)

Features and Benefits of Immersion Heaters

ANSI and ANSI compatible 2, 2-1/2, 3 thru 48 inch flanges which provide appropriate heater size-to-application and fit. Element sheath and flange materials to meet your application needs. Integral thermowells provide convenient temperature sensor insertion and replacement without draining the fluid being heated. In addition, standard, general purpose terminal enclosure offers easy access to wiring.

Moreover, element support(s) provides proper element spacing to maximize heater performance and life. All units have inspection and/or testing which ensures element-to-flange pressure seals do not leak. The eyebolts or lift lugs for eye bolts, on three inch and larger flange heaters, have drill and tapping to facilitate lifting during installation.

In addition, WATROD hairpins are repressed (recompacted) which provide improvement of heater life, insulation resistance and heat transfer. Also, branch circuits are designed for 48 amperes per circuit maximum which reduces risk of failure due to excessive temperatures generated by high amperage.

We provide engineering and product support for your application.