Description

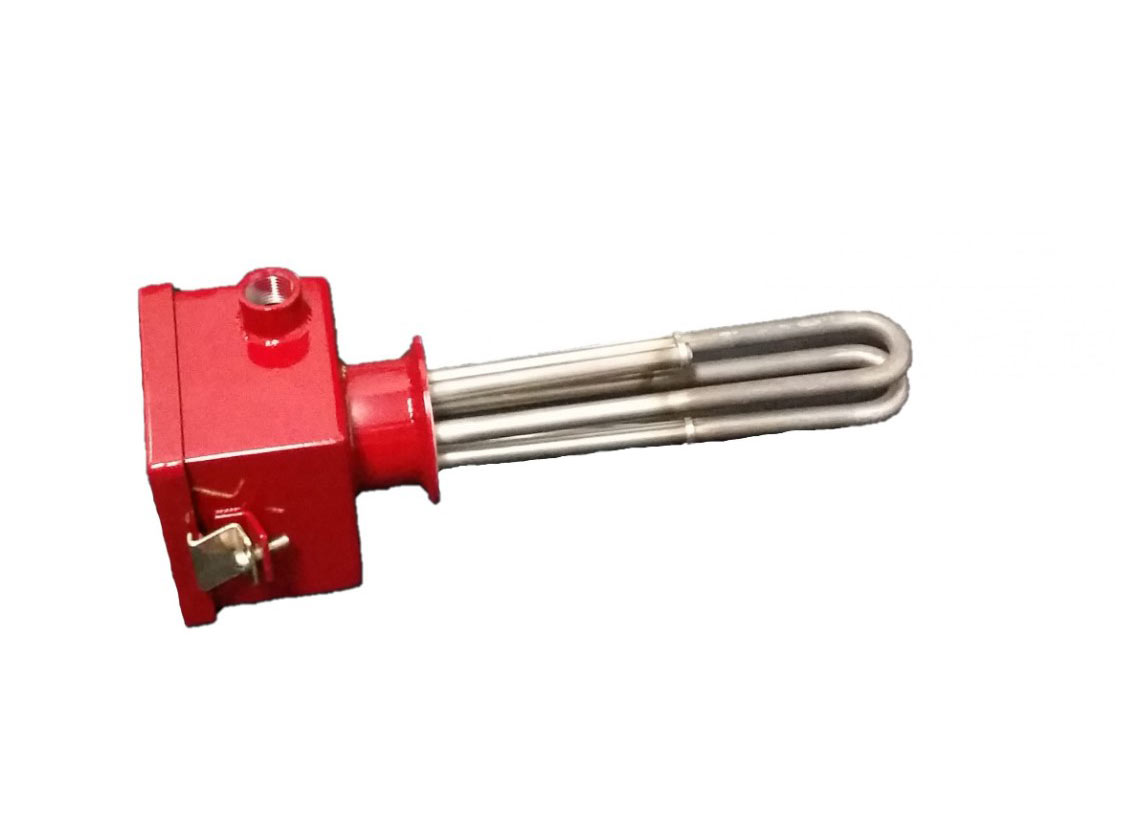

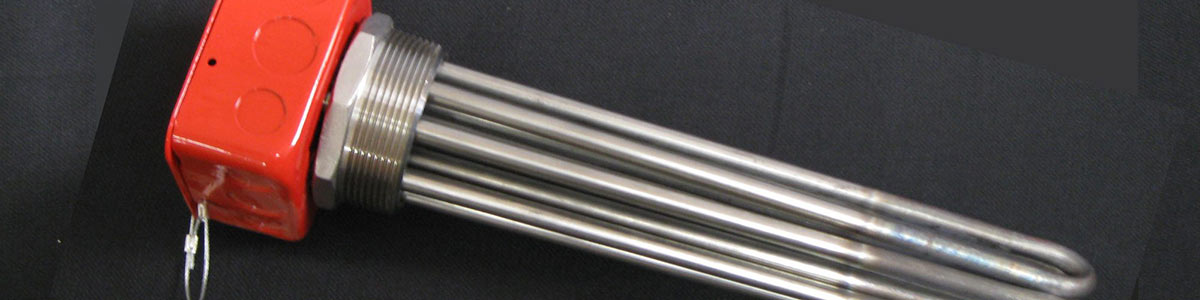

Glo Quartz screw plug immersion heaters are used by the process heat industry for a wide range of applications. This type features a broad selection of screw plug sizes, wattage, materials and terminal box types. Screw plug heaters may be threaded directly into a sufficient tank wall or used with a companion coupling. Screw plug heaters are mainly made for horizontal use, longer cold zones are available for vertical installations. Glo-Quartz screw plug immersion heaters offers NPT and British parallel threads.

Benefits of Screw Plug Immersion Heaters

100% Utilization of energy

Heaters available with various wattage and voltage combinations

Low watt density available for oil heating or other viscous solutions

Minimum resistance to free flowing and circulating solutions

Thermostat control available

Electro-polish available for 316 SS and Alloy 800 elements

UL Recognized / CSA Certified up to 18 KW, 600 VAC, on most heaters

Three critical elements to remember

Corrosion: Not all metals can handle all solutions. Corrosion is a leading cause for premature heater failure. Determining factors involve sheath materials, watt densities and solution concentrations.

Wiring: All heaters should be installed by a licensed electrician.

Electropolishing: Electropolishing is the controlled electro-chemical removal of surface metal, resulting in a brilliant appearance and improved properties. Sometimes described as “Reverse Plating”, the process has a leveling effect, which produces smoothness and increased reflectivity. Most printed circuit board applications where heating de-ionized water is used in a “clean room” environment requires electropolished heating equipment.

More importantly, the outer layer of the metal is removed, leaving a passive surface free of imbedded contaminants and prevents corrosion in tank heaters, screwplug, flange, and circulation (in-line) heating applications. Glo-Quartz® offers electropolish as an option to prevent sludge build-up and provide a longer heater life.

The Benefits… The best effects is on stainless steel, but good results can also be with nickel alloys. Benefits Include: superior micro-finish, corrosion- resistance and lustrous appearance. In addition, benefits include burr removal, micro-sizing to close tolerances, and cleanliness detection of surface defects. Moreover these immersion heaters have extended fatigue life, and reduced friction and galling.

—

We provide engineering and product support for your application.